Quality Control & Business Negotiation

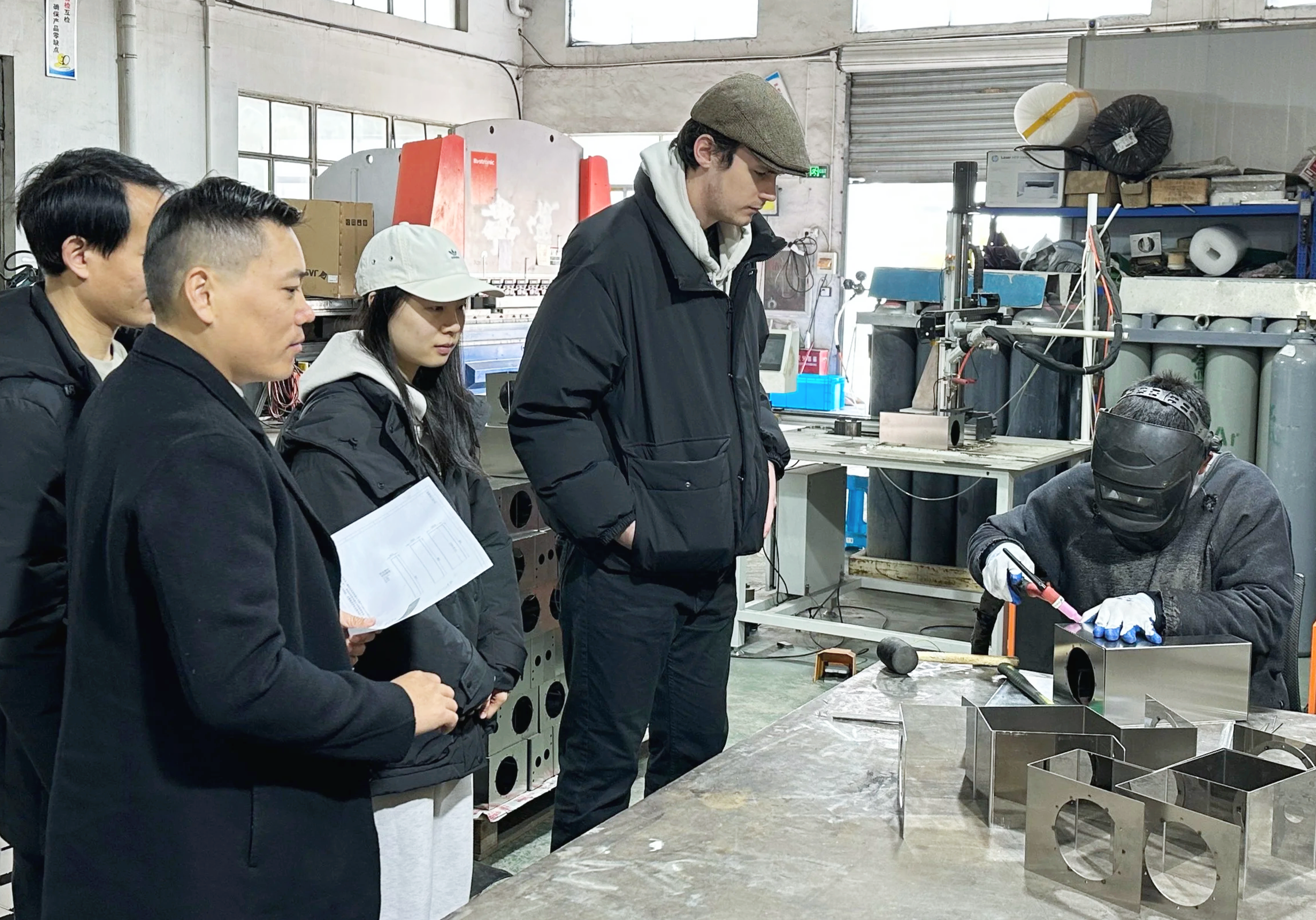

Our quality control and business negotiation service covers every stage of your supplier relationship — from factory visits and production checks to in-person communication and negotiation support. We conduct on-site inspections to ensure your products meet agreed standards, while also representing your interests during key supplier discussions.

Importantly, having a foreign product expert present on-site adds real authority and pressure for suppliers to maintain quality. When inspections and negotiations are conducted to Western expectations, suppliers are far more motivated to keep quality consistent and avoid cutting corners.

Three-step Inspection

Our three-step inspection process safeguards quality at every stage — from factory conditions, through production, to the final shipment. Each inspection is conducted by our American product expert together with a local Chinese specialist, ensuring both technical precision and seamless communication.

All findings are thoroughly documented with photos, videos, and a detailed written report — giving you a clear view of your supplier’s operations without the need to travel.

We carry out comprehensive, in-person inspections of your supplier’s facilities, evaluating cleanliness, organization, worker safety, and compliance with best practices.

I. On-Site Factory Inspection

II. Production Inspection

We oversee your products during manufacturing to ensure they meet agreed specifications and quality standards. This includes verifying raw materials, reviewing production methods, and conducting spot checks at key stages.

By identifying issues early, we help you avoid costly errors, delays, and defective shipments.

III. Pre-Shipment Inspection

Before goods leave the factory, we perform a final inspection to confirm product quality, packaging, labeling, and order accuracy.

This last check ensures that only compliant, properly finished products are shipped, protecting you from unexpected problems on arrival.